Automatic Tie Sheet Dispenser

The automatic tie sheet dispenser is a modern device designed to improve the efficiency of the logistics and packaging industries. It is able to automatically dispense bottom sheets (also known as tie sheets or liner sheets), greatly reducing the need for manual operation and improving work efficiency and accuracy.

First, the main function of the automatic tie sheet dispenser is to automatically dispense pre-cut bottom sheets to designated locations. These bottom sheets are often used to provide additional stability and protection when goods are stacked, preventing the goods from sliding or tilting during transportation. By using automated equipment, companies can ensure that the size and position of the bottom sheets dispensed each time are accurate, avoiding errors caused by manual operation.

Second, the automatic tie sheet machine is usually equipped with advanced control systems and sensors. These systems can monitor the operating status of the machine in real time to ensure that the dispensing process of each bottom sheet proceeds smoothly. For example, when the machine detects that the number of bottom sheets is insufficient, it will automatically sound an alarm to remind the operator to replenish it. In addition, these machines can also be adjusted according to different types and sizes of goods to ensure that the size and quantity of the bottom sheets are suitable for specific needs.

The application of bottom sheet dispenser in the packaging and logistics industries is very extensive. It can be used not only for stacking and transporting ordinary goods, but also for cold chain logistics and packaging of high-value goods. Since the automatic tie sheet machine can significantly improve work efficiency, many companies have begun to introduce this equipment in their production lines to reduce labor costs and improve packaging quality.

In actual operation, the use of the automatic tie sheet dispenser is very simple. The operator only needs to load the film material into the machine and set the corresponding parameters, and the machine will automatically complete the cutting and distribution of the film. This not only saves time, but also reduces the errors and risks that may be caused by human operation.

In summary, as an efficient and reliable automation equipment, the automatic tie sheet dispenser is gradually becoming an important tool in the logistics and packaging industries. It not only improves production efficiency, but also ensures the stability and consistency of packaging quality, bringing significant economic benefits and competitive advantages to enterprises.

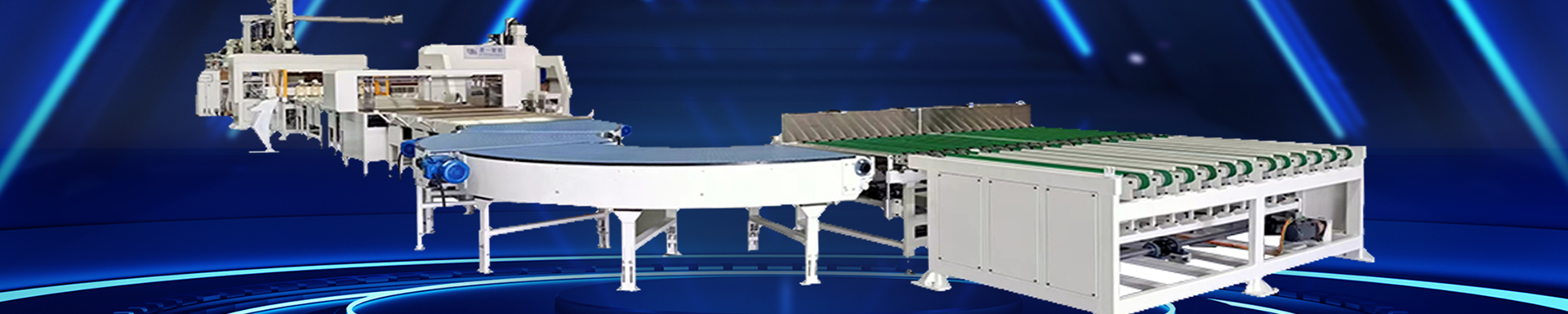

Equipment introduction : Tie sheet device

1. Sheet storage: adopts vacuum reversing valve and magnetic valve control to adsorb the paper to the appointed position;

2. The cylinder on the special fixture for cartons extend to grip paper, then the robot will take the paper.

3. Paper padding function: It can pad paper until palletizing to the top, and ensure that the cartons will not fall down during transferring.

4. It stores paper on the platform, When the cardboard is smaller than the sucker size, it will not absorb the paper and loose.

5. Pad Paper Store Rack

Store and drawing the pad paper, at the specific layer set to put the pad paper to protect the bundle cartons from falling down. Automatic drawing through the suck disc and air cylinder.

Size: 1200W x 800L x 1600H

Pad Paper size : Max size same as Pallet size

Pad Paper requirement : Size neat and fixed

Pick and Lay time 5 Seconds

Pad paper size : Max. same as the pallet size